The cost of these losses is on top of an already very expensive brewing cycle and equipment itself through to the trucks, pallets, vessels, taps & pumps needed to pour beer. There has been a huge amount of work done by brewers and trade bodies in bringing awareness and advice to minimising these losses in recent years, with some amazing results, and I’d like to think we’re bringing something new to both reducing keg losses, reducing the fixed cost to entry, and helping more great beer get into more peoples hands.

Lots of operators track vehicles to maximise efficiency, warehouse management systems are more prevalent and intelligent with pallets & batch codes of products being tracked for many reasons, brewers have in venue quality programmes for their beers to ensure consumers get a great experience & now you can track a Kegstar keg from the brewery right through to venue to help with all of the above and in doing so help keep asset cost and loss down.

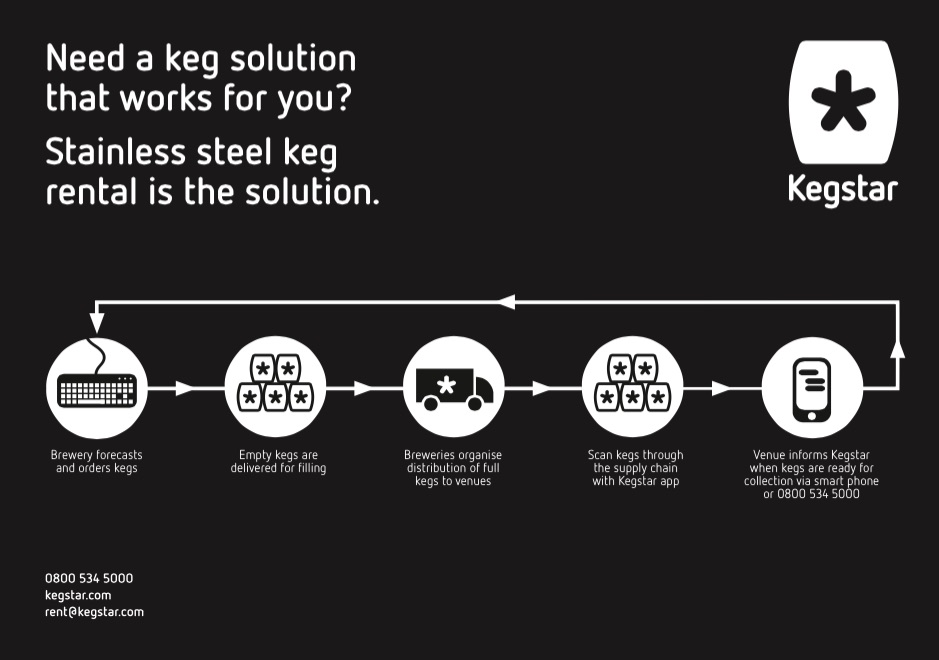

Our model is simply rent, fill, deliver, repeat and all underpinned with app enabled technology (iOS & android). The Kegstar keg is scanned (via the app and our 2D QR codes on the keg) at each key stage in the supply chain which means the brewer knows how long the keg has travelled through each stage of the route to market right through to venue. In turn this drives the rental fees applicable and some useful insights including how long a keg took to pour at venue.

Consumer experience drives brand success and the quicker a keg takes to travel through the supply chain and pour, the better the experience is likely to be. The venue can request collection of the empty keg via the app, email or phone and the Kegstar team will collect within 48 hours to repeat the cycle, which should help with the unsightly empties hanging around on site. When this is done there is a notification to both the brewer and the venue that it’s time to sell or order some more great beer.

So if capital is hard to come by, or beer freshness can be an issue, or you need to flex the keg fleet at key periods without a longer term commitment then I hope we can be the answer with our clever kegs wrapped around some great beers to create more happy drinker experiences whilst reducing this farcical trend in keg loss and cost in the UK and beyond.

Disclaimer: These comments portray Christian Barden, general manager of Kegstar’s, views on the sector.

Why Keg Tracking is Key | Kegstar

The cost of these losses is on top of an already very expensive brewing cycle and equipment itself through to the trucks, pallets, vessels, taps & pumps needed to pour beer. There has been a huge amount of work done by brewers and trade bodies in bringing awareness and advice to minimising these losses in recent years, with some amazing results, and I’d like to think we’re bringing something new to both reducing keg losses, reducing the fixed cost to entry, and helping more great beer get into more peoples hands.

Lots of operators track vehicles to maximise efficiency, warehouse management systems are more prevalent and intelligent with pallets & batch codes of products being tracked for many reasons, brewers have in venue quality programmes for their beers to ensure consumers get a great experience & now you can track a Kegstar keg from the brewery right through to venue to help with all of the above and in doing so help keep asset cost and loss down.

Our model is simply rent, fill, deliver, repeat and all underpinned with app enabled technology (iOS & android). The Kegstar keg is scanned (via the app and our 2D QR codes on the keg) at each key stage in the supply chain which means the brewer knows how long the keg has travelled through each stage of the route to market right through to venue. In turn this drives the rental fees applicable and some useful insights including how long a keg took to pour at venue.

Consumer experience drives brand success and the quicker a keg takes to travel through the supply chain and pour, the better the experience is likely to be. The venue can request collection of the empty keg via the app, email or phone and the Kegstar team will collect within 48 hours to repeat the cycle, which should help with the unsightly empties hanging around on site. When this is done there is a notification to both the brewer and the venue that it’s time to sell or order some more great beer.

So if capital is hard to come by, or beer freshness can be an issue, or you need to flex the keg fleet at key periods without a longer term commitment then I hope we can be the answer with our clever kegs wrapped around some great beers to create more happy drinker experiences whilst reducing this farcical trend in keg loss and cost in the UK and beyond.

Disclaimer: These comments portray Christian Barden, general manager of Kegstar’s, views on the sector.

ARTICLES

Decoration | Why flexibility is key

Big Drop awards license to Keystone

New printer for craft breweries

Thornbridge toasting 20 years

PODCASTS