Fruit additions can add complexity and layers to your beer. In this piece, high quality natural ingredients supplier Kanegrade, outlines some of the options available to you if you’re looking to work with the wonder world of fruit.

Purees and puree concentrate contain juice as well as the fibrous material from the fruit, to be used in applications such as smoothies.

They are offered with or without sugar, with or without seeds, and we also have puree concentrates available where water is removed to strengthen the flavour.

As worldwide suppliers of fruit juice concentrates, ranging from Apple to Watermelon and every fruit in-between.

The pure juice is concentrated and filtered into a liquid which can be used in a multitude of applications or even simply diluted back to pure juice strength. We also offer de-ionised concentrates for natural sweetening, and clear and cloudy varieties.

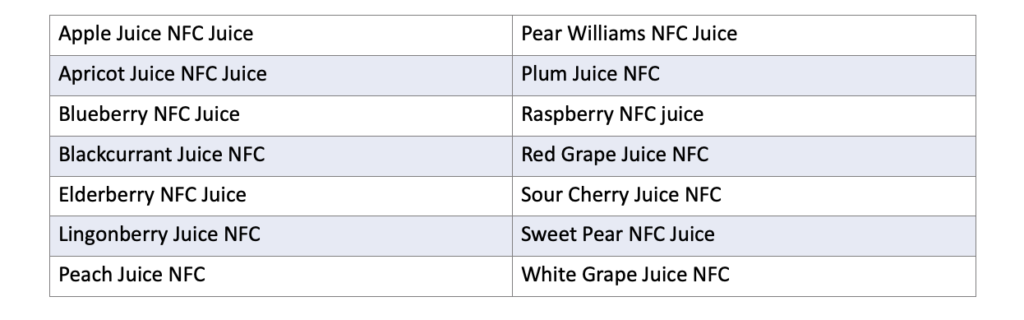

NFC Juice stands for ‘not from concentrate’ and is normally pressed and filtered juice in its pure form.

This can simply be packed and used in beverages, or used to introduce fruit flavour in other applications. NFC juice is not normally subject to any high-temperature processing.

To create NFC juices, fresh sound fruits are cleaned and mechanically milled to extract the juice. This is then filtered and pasteurised before being filled into the packaging of choice.

Table 1

We are proud to produce a wide range of fruit powders. They are used in hundreds of applications including plant based foods, confectionery, sauces, protein mixes, fillings and many more. Consumer interest in plant based products is at an all time high with many people choosing a plant based diet.

The main reasons being it can be better for your health, it can assist in losing weight, it is a good diet variation, it’s good for the environment and it can save you money.

A plant based diet is usually made up of foods which come from plants, which includes fruit powders.

These are fine, normally highly soluble powders with long shelf life, making them ideal for use in food manufacturing.

Spray-dried fruit powders can be used to create a powder from fruit juice. The juice is normally concentrated and pasteurised, mixed with a carrier to ensure stable drying and then fed into the spray-dryer.

The mixture is then pumped through a tiny nozzle and into a heated chamber with a vortex of hot air. This causes rapid evaporation of the water in the mixture, resulting in the fruit powder to be collected at the outlet.

Roller, drum or belt-dried fruit powders are the most basic type of fruit powder. In this process fruit is passed along a set of rollers through a heated chamber (Roller-Drier), tumbled in a heated drum chamber (Drum-drier) or passed along a belt conveyor through a heated chamber (Belt-drier).

This high-temperature process removes as much of the water as possible, and then the dehydrated fruits are milled/ ground/ crushed into a fine powder.

Vacuum-dried fruit powders are a more specialist way of producing a fruit powder, which avoids exposure to high-temperature.

The fruit are dried in a similar way to the roller/ belt/ drum, however as a batch process in a sealed vacuum-chamber.

The vacuum lowers the boiling point of water to around 30°C, meaning a lower temperature is required to evaporate the water from the fruit.

The resulting fruit can then be milled/ ground/ crushed into a powder. This is suited to temperature-sensitive fruits, and whilst more expensive, it’s less harsh on the fruit preserving more flavour.

Freeze-dried fruit powders are the product of a batch process, which takes place in a sealed chamber. The fruit is frozen and then the pressure is gradually reduced, which makes the water in the fruit jump directly from the solid phase (ice) straight to the gas phase (vapour).

This is a process known as ‘sublimation’. The water vapour is free to leave the fruit, resulting in highly dehydrated fruit with the integrity fully maintained.

As before this fruit can then be milled/ ground/ crushed into a powder. This is an expensive process resulting in the highest price fruit powder but arguably most preserved.

So, how to choose?

Each fruit has a particular process from each of the above which suits it the most and is most commonly used.

This decision is based on a blend of reasons including: feasibility of manufacture, cost, quality of final product required. To find out which process from above is used for the fruit powder you need, then please enquire.

Note: not all fruit powders are pure fruit solids, many have carriers so consist of a proportion of fruit solids along with a proportion of carrier.

The carrier can have multiple roles including: maintaining shelf life, facilitating use in application, anti-caking. Carriers are processing aids and therefore do not have to be declared on labels (EU Law).

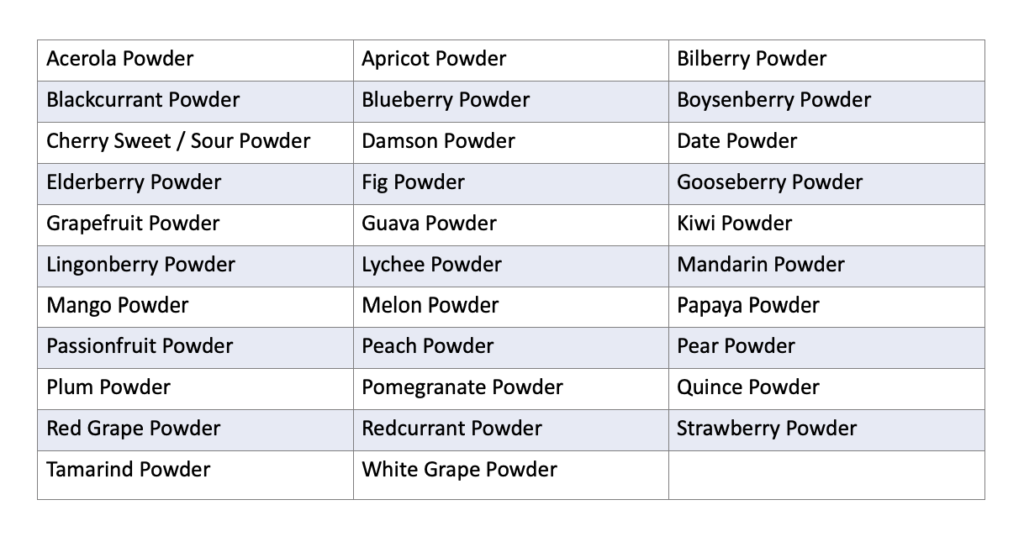

Our range contains more than 30 fruits with our most popular including lemon powder, lime powder, orange powder, apple powder, raspberry powder, banana powder and more. These are referenced below.

Table 2