Housed in a Grade II listed mill in the spiritual heart of the industrial revolution, Northern Monk takes thousands of years of monastic brewing heritage and tradition and combines them with the best of modern brewing techniques along with local and internationally sourced ingredients.

All of Northern Monk’s beer is brewed in-house to produce products unique in their taste, colour and origins. Brewing 20,000 pints per week for distribution around the world, Northern Monk work with charitable organisations and local businesses and collaborate with breweries and businesses who share their vision of craftsmanship and quality to help strengthen the North.

Northern Monk started brewing in 2014 and has since become an institution of innovation in brewing, with a focus on quality, which is largely monitored in-house using a variety of lab equipment including the CDR BeerLab.

With this in mind, it is no surprise that head brewer Brian Dickson and Production Manager Colin Stronge were keen to use their BeerLab in our latest study to investigate the effect of dry-hopping on fermentable sugars and ABV.

The project

An article published in the Journal of the Institute of Brewing in 1941 by Janicki, J. et al[1] discussed the presence of diastatic activity in hops and how this might affect secondary fermentation on in cask beer. Their experiments consisted of taking samples of starch dissolved in pH adjusted water (to approximate beer pH) and adding Saaz hops at a rate of approximately 40 g/L. The research discovered that maltose was produced from dry-hopping in mg quantities in just five hours, suggesting that the starch in solution was being broken down by enzymes in the hops.

Ron Pattinson points out in his blog (March 2018), that Brown and Morris also commented that hops contain a noticeable percentage of glucose and fructose (around 3%), which was also shown to be fully fermentable after extraction from the hops and addition of yeast.[2,3] Part two of Ron’s blog post also revisits the work published by Janicki et al, further discussing the ability of hops to break down starch into fermentable sugars.

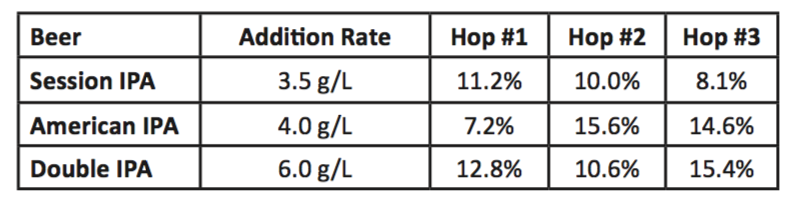

To best investigate these two effects, we picked three beer styles of increasing dry-hop quantities, namely a session IPA, an American IPA and a DIPA. The increasing levels of dry-hopping – all via a hop rocket – should give increasing levels of diastatic activity and fermentable sugar addition and potentially an increase in ABV.

The results

For the study, a sample was taken from the FV every 30 minutes, with two samples taken before dry-hopping and two samples taken after dry-hopping. All three beers were dry-hopped for 3-hours using a hop rocket and all samples taken were analysed for ABV, fermentable sugars (g/L), Starch (g/L), pH, and bitterness (IBU) using the CDR BeerLab. The starch measured on the BeerLab will include a mixture of complex starch molecules not broken down in the mash as well as some longer chain dextrin molecules. Fermentable sugars is a measure of glucose, fructose, maltose and maltotriose.

The American IPA and DIPA were not dry-hopped before running the hop rocket and therefore not before analysis, however the Session IPA was dry-hopped prior to using the hop rocket and analysis. The hops used in each dry-hopping varied by addition rate and alpha acid % as shown in Table 1.

American IPA and DIPA

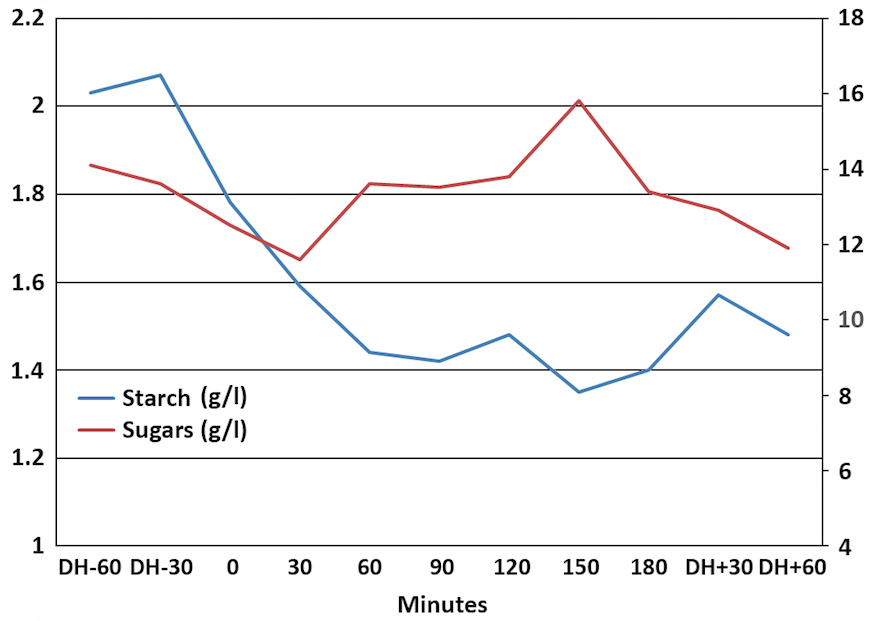

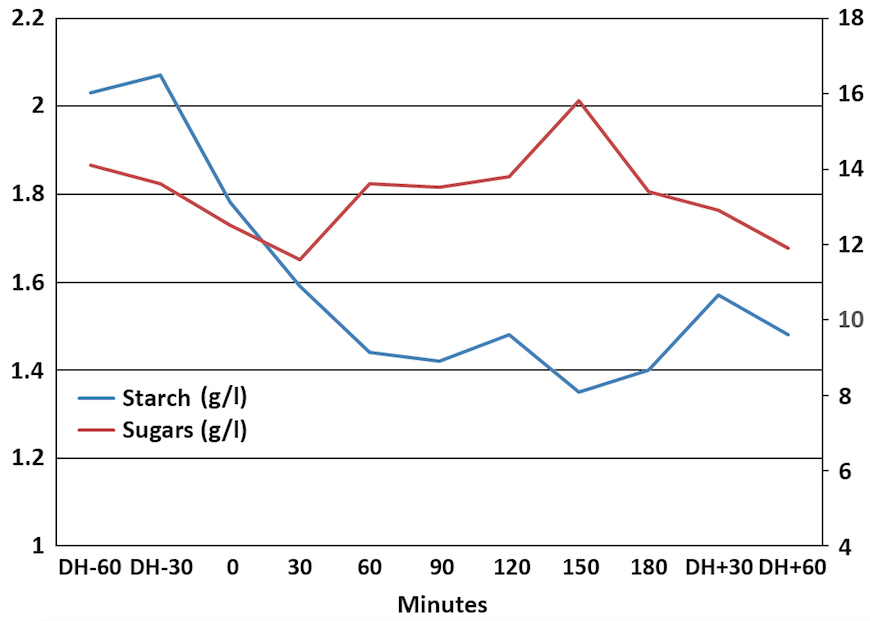

The two most notable results came from the American IPA and the DIPA as expected, both beers showing high initial starch which drops as fermentable sugars increase. As shown in Figures 1 and 2 the American IPA has a starch concentration beginning around 2 g/L and dropping to a level of around 1.5 g/L, this drop is exaggerated in the DIPA with a drop from around 1.8 g/L to just over 0.5 g/L.

The fermentable sugar concentration looks slightly more variable with an initial drop in value followed by a peak, this can be explained by yeast being roused back into suspension from circulation of the hop rocket and absorbing some of this sugar. The peak in sugar concentration could come either from the diastatic power of hops on the residual starch or from the addition of fermentable sugars in the hops themselves.

Figure 1

Figure 1. American IPA Sugar Vs Starch

Figure 2

Figure 2. DIPA Sugar Vs Starch

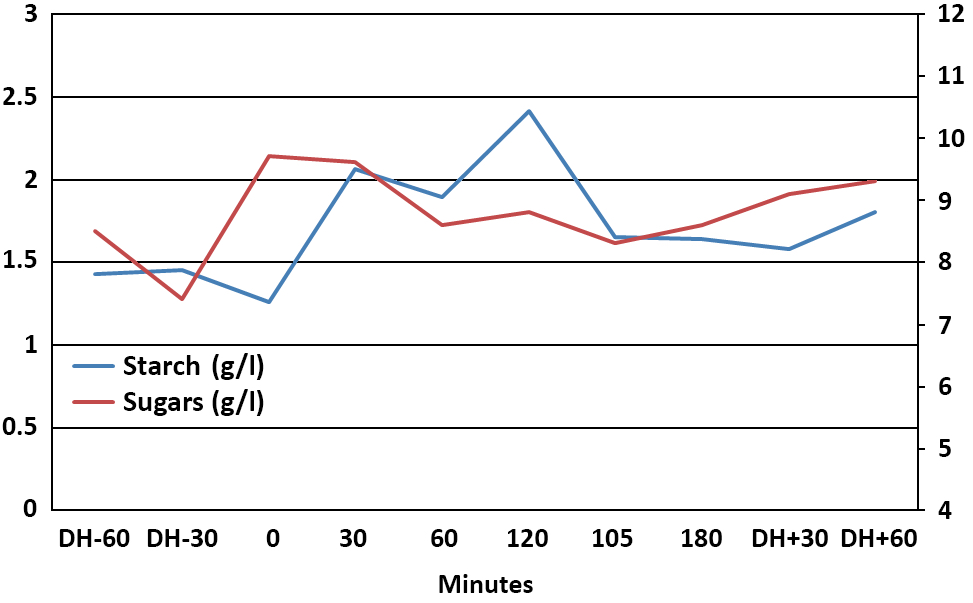

Figure 3

Figure 3. Session IPA Sugar Vs Starch

Session IPA

As mentioned previously, the Session IPA was dry-hopped prior to initiating the hop rocket and as can be seen in Figure 3 the starch does not exhibit a drop in concentration, there is however a slight rise in sugar concentration. This may be due to the initial dry-hopping breaking down all of the simple starch and leaving only complex starch molecules, meaning that the second dry-hopping by hop rocket could not break down any more starch, but could add some sugar.

It is clear to see in Figure 1 and 2 that hops are having a demonstrable effect on starch reduction and sugar production, which ultimately will lead to further fermentation in the beer – potentially giving a higher ABV than expected in the finished/packaged beer compared to during dry-hopping.

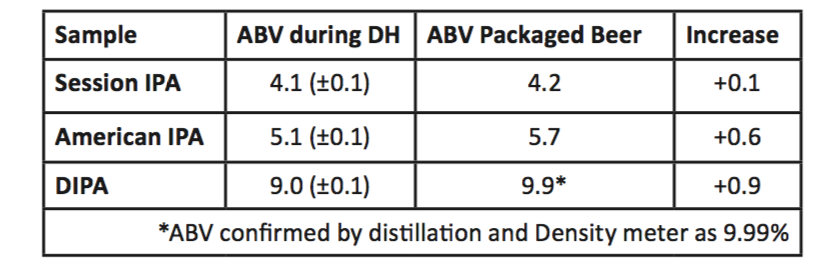

Apart from the natural variation of ABV on the BeerLab (±0.1) there was no significant increase in ABV during the dry-hopping, however as can be seen in Table 2 there is an increase in ABV value in the finished, packaged beer. The increase for the Session IPA is negligible, however for the American IPA and the DIPA there is a significant jump in ABV, which correlates with the Sugar Vs Starch graphs above.

To confirm accuracy of the finished beer results, the DIPA was tested by distillation and Density meter giving a result of 9.99% ABV.

Conclusion

It is apparent that the addition of dry-hops to a beer at the end of natural fermentation will contribute to a reduction in residual starch and an increase of fermentable sugars. This can be explained by two effects; diastatic enzyme activity present in the hops, breaking down starch into fermentable sugars; contribution of fermentable sugars from the hops themselves.

By increasing fermentable sugars near the end of fermentation, yeast will continue to ferment beyond when the brewer believes fermentation has finished, causing an increase in ABV, which may not be accounted for with gravity readings.

References

Janicki J., Kotasthane W. V., Parker A., Walker T. K.; J. Inst. Brew.; 1941; Vol. 47; pp. 24 – 36.

Brown H. T., Morris H.; J. Inst. Brew. (The Brewers’ Guardian); 1893; Vol. 6; pp 93 – 94.

http://barclayperkins.blogspot.co.uk/2018/03/why-dry-hop.htm