Ingredients and Processes

Talk to brewers producing mainstream brands and consistency is in danger of being the only element of quality. Vary the product by 2% and quality is out of the window. Vary by more than 10% and your job flies out the door.

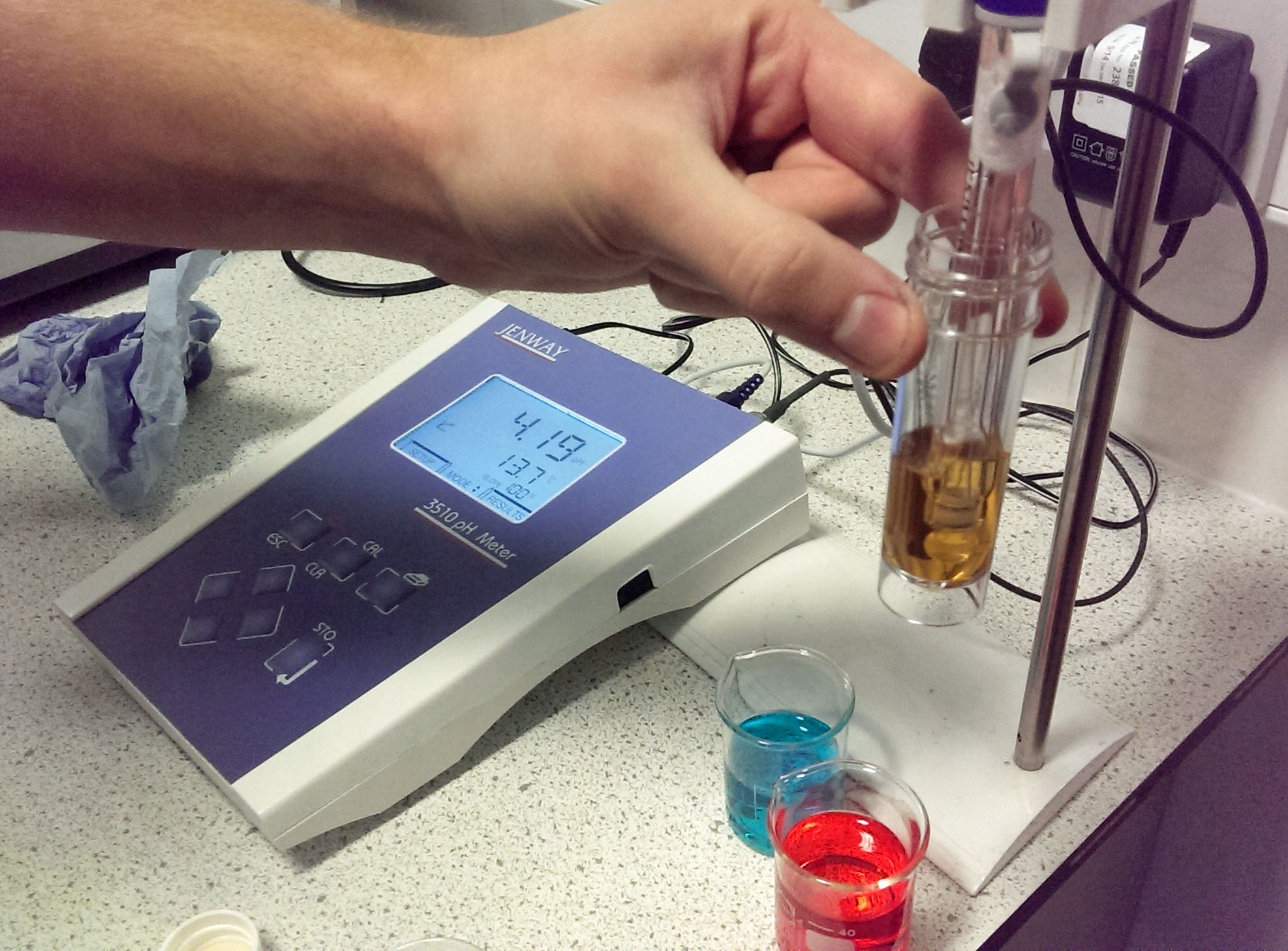

Ingredients and processes are fine tuned to achieve a target specification, often defined chemically and involving blending and amending to ensure that variations are not detectable.

In part this may be because mainstream beers tend to be drunk by dedicated regulars who become very sensitive to minute differences. They drink in the same bar and become highly attuned to a beer’s character.

This is, of course, very different from the vintage wine ethos where difference is reservedly applauded. And also at an extreme from the artisan brewer also producing vintage products, intentionally different by the batch.

Today’s brew is unique, in numbered bottles and sold with the artisan’s signature on every bottle – and, inevitably, sold at extravagant price. In truth the latter is a fine ambition but rarely achieved to support a viable business model.

Nevertheless, it could be argued that drinkers dedicated to craft ales will experience much greater variety in their pursuit of microbrewery beers and, perhaps, be more forgiving to subtle changes.

Quite a few years ago we first produced Evolution ale from the Darwin Brewery at the University of Sunderland.

Ostensibly a training exercise for Brewlab it would evolve with every course, differ by the month and excite attention by its changes. Of course this never happened. After three brews the recipe settled to a character preferred by customers.

Once a beer is accepted it takes courage to make speculative changes – just witness the outrage when a national beer alters its abv or, for example, when a well-known brand of chocolate removed their commitment to pour pints of pure milk into every bar.