Quality and Consistency

This tension between quality and consistency is by no means a conflict but a dynamic whereby a brewery can develop a reputation for reliability but also originality. Originality is needed to develop a product, consistency to ensure continual acclaim.

In some cases mainstream brands are supplemented with seasonal selections and celebratory ales. Crossovers occur and a successful seasonal is included in the mainstream. In other cases blends allow common characters to be recognised in different beers.

So considering the importance of achieving quality beers what are the factors for a diligent brewer to address? It would be easy to make a list starting with liquor and ending with labels and perhaps we can address these at future dates.

In general terms let’s consider quality as the two elements of assurance and control so there is a framework into which data can be placed and assessed.

Assurance has two time points – assuring ourselves as brewers that the beer about to be produced will achieve the quality and character we intend. In addition though we need to assure customers that a fault which has occurred won’t happen again.

While the first of these assurances is a matter of planning the second is one which requires action based on records and data, not just hopeful promises. Quality assurance is the structure we need to achieve these and provides the evidence to demonstrate consistency – and, where necessary, to inform improvements where inconsistency crept in.

In many industries legions of quality professionals engage in accredited systems to measure all manner of specifications, input volumes of data and collect swathes of signatures. Even toilets are now awash with such assurances. In brewing we typically keep a brew log with the details of each gyle brewed.

Started on the day of brew it is an easy document to leave half-finished omitting an assessment of the final result.

Easy because each day typically sees the start of a new gyle and a fresh sheet to complete. Given a problem it is often this second half which contains the information to limit a repeat of the same – finishing gravity, yeast count at rack, contamination assessment, taste profile – or just a taste impression.

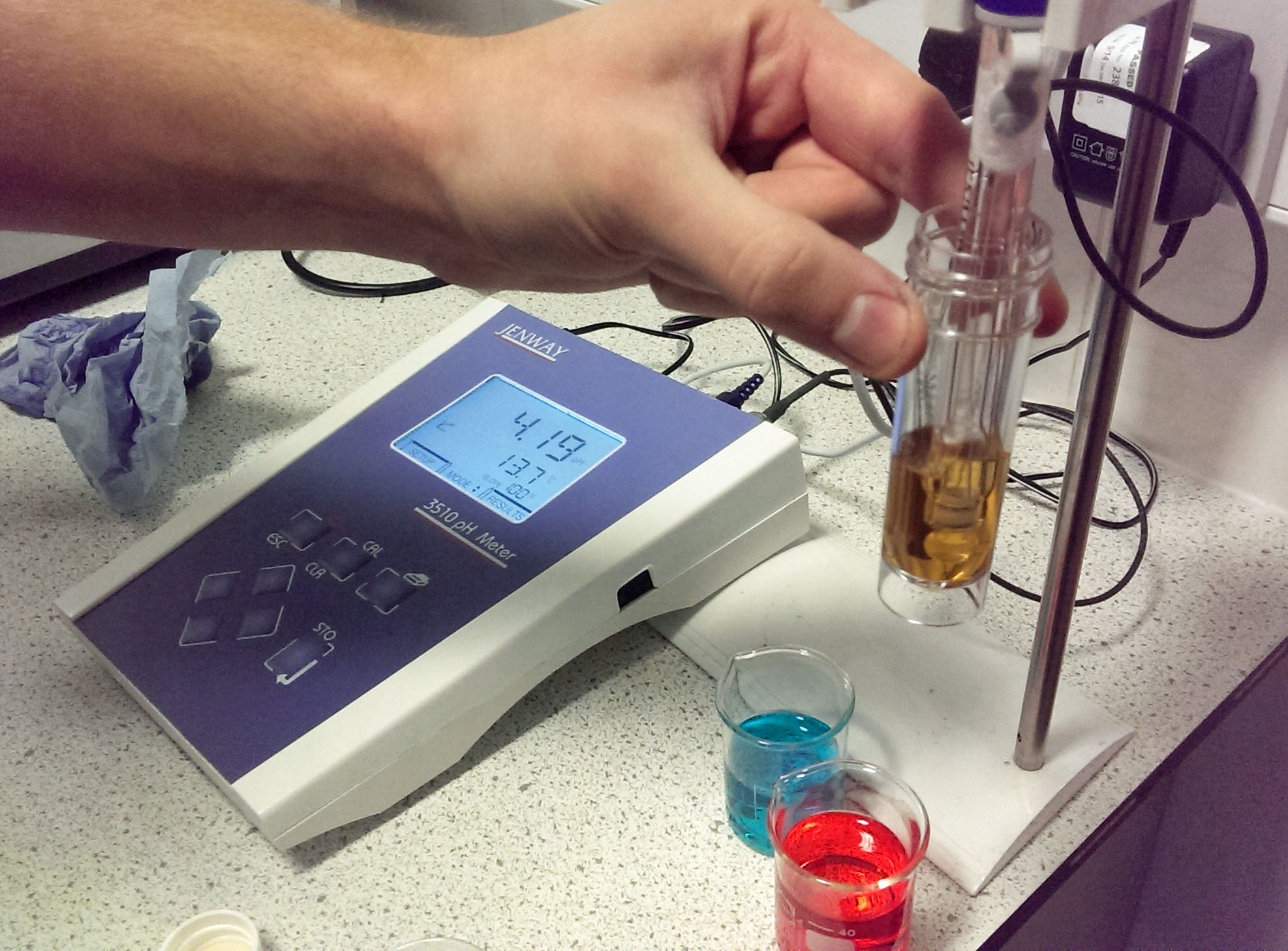

In some cases more detailed results from the laboratory are appended but not always integrated into a track record or trend analysis.

Quality assessment is needed to advise your quality assurance and to instigate how quality can be controlled in the future. Integration is key here so that key indicators are tracked and variations noted.

A common example is to plot the final gravity of each brew and note whether there is a progressive difference against the expected for each brand.